PCB Board Defects with Anomaly Detection

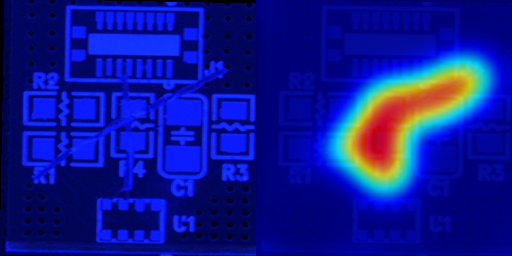

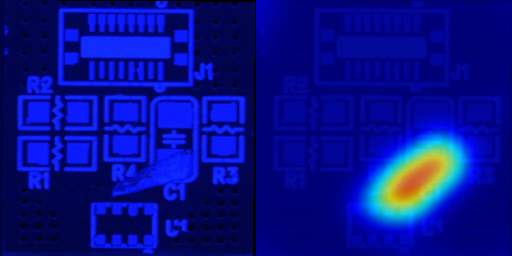

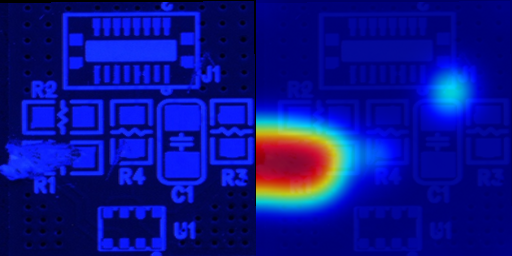

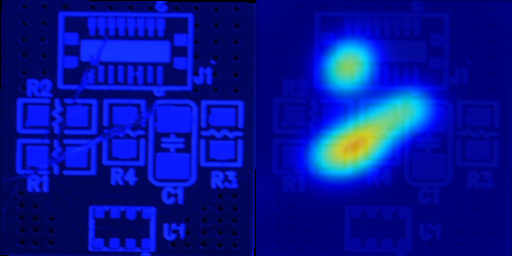

Heatmap anomaly localization · Reduced labeling · Production-friendly post-processing

Overview

This project targets defect detection on PCB boards (e.g., short circuits, missing/extra patterns, irregular traces) where labeled defect samples are limited. The system produces pixel-level anomaly heatmaps and a final OK/NG decision using robust scoring and post-processing.

Problem

- Defects are rare and diverse → hard to collect balanced labeled datasets.

- Small defects need localization, not only classification.

- Variations in lighting/PCB layouts can cause false alarms.

Solution

- Train mainly on normal samples (unsupervised/weakly-supervised anomaly learning).

- Generate anomaly heatmaps → localize suspicious regions.

- Compute defect score from ROI heatmap stats (max/mean) and apply tuned thresholds.

- Post-processing: smoothing + morphology + connected components for stable decisions.

My Role

- Designed the end-to-end anomaly pipeline producing heatmap-based defect localization.

- Handled limited labels with anomaly learning strategy and strict validation.

- Optimized post-processing and thresholds for robust decisions in production.

Implementation

Language: Python

Libraries:

PyTorch

OpenCV

NumPy

Outputs: Heatmap · Binary mask · Defect score · OK/NG decision

Deployment notes: ROI cropping + threshold tuning per PCB type for stable performance

Anomaly Map Gallery

Training Demo

Short clip showing the training process / anomaly map learning.