Gesture Recognition System for Laser Machine Safety Control

ToF detection · 6 gesture classes · Time-series classification · Real-time safety

Overview

Two-stage safety system for laser machine control: human detection stage followed by 3D time-series gesture classification. Recognizes 6 different gestures using Time-of-Flight (ToF) sensor data with low latency for real-time safety control.

Problem

- Safety-critical application requiring near-zero latency.

- Need to distinguish 6 different gesture classes reliably.

- 3D ToF data requires specialized time-series processing.

- False positives could cause production disruption.

Solution

- Two-stage pipeline: human detection → gesture classification.

- Time-series classifier designed for 6 gesture classes from ToF data.

- Latency reduction through optimized inference pipeline.

- Robust validation under various operational conditions.

My Role

- Built human detection stage and gesture pipeline with ToF data.

- Designed time-series classifier for 6 gesture classes.

- Optimized latency reduction for real-time safety control.

- Validated system under production environment conditions.

Implementation

Language: Python

Libraries:

PyTorch

OpenCV

Sensor: Time-of-Flight (ToF) camera

Gestures: 6 classes for laser machine control

Results Gallery

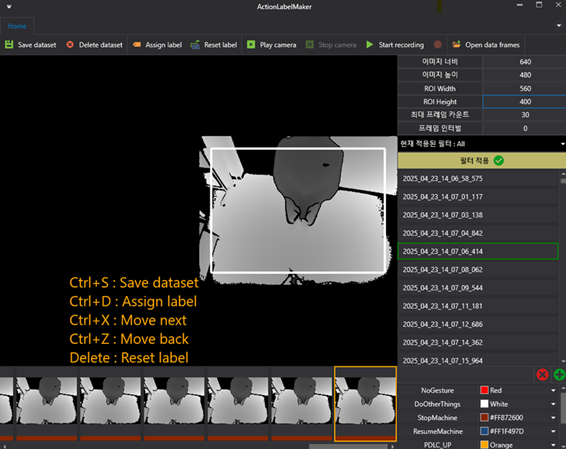

Real-time gesture recognition system demonstration.

Gesture recognition Inference visualization

End Result

- Real-time safety gesture recognition system for laser machines.

- Low-latency classification suitable for safety-critical applications.

- Robust performance across 6 gesture classes with ToF data.