Sebang EV Battery Inspection System with AI

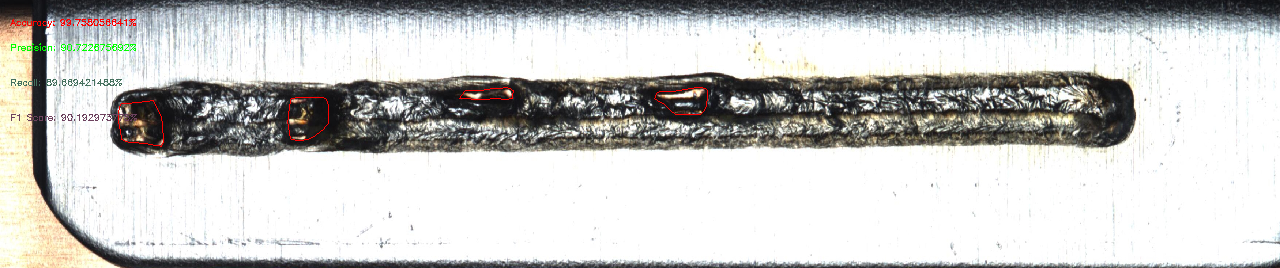

U-Net segmentation · Weld measurement · Pinhole & spatter detection

Overview

EV battery welding inspection system using U-Net based segmentation for pinhole/spatter detection and weld size measurement. Critical for battery safety and quality in electric vehicle manufacturing.

Problem

- Battery welding defects critical for safety and performance.

- Need to detect pinholes, spatter, and measure weld size.

- Challenging imaging conditions with metallic surfaces.

- Requires automated measurement for quality standards.

Solution

- U-Net based segmentation for welding defect detection.

- Automated measurement for weld size and defect severity.

- Optimized for consistent industrial performance.

- Multi-class defect recognition (pinholes, spatter, etc.).

My Role

- Developed U-Net based segmentation for welding defect detection.

- Implemented measurement for weld size and defect severity.

- Optimized for consistent industrial performance.

Implementation

Language: Python

Libraries:

PyTorch

U-Net

OpenCV

Defects: Pinholes, spatter, weld size deviation

Results Gallery

Demo Videos

Real-time inspection system in action.

End Result

- Accurate welding defect detection with automated measurement output.

- Improved EV battery quality and safety standards.

- Deployed successfully in Sebang production line.