Automated Ampule Inspection System with Deep Learning

Detection & segmentation · Quality assurance · Production deployment

Overview

Deep learning-based ampule inspection system for defect detection and quality control. Automated pipeline ensures pharmaceutical-grade quality standards with high reliability.

Problem

- Pharmaceutical industry requires stringent quality standards.

- Various defect types: cracks, particles, contamination, fill level.

- Transparent glass ampules create challenging inspection conditions.

- Need for reliable automation to replace manual inspection.

Solution

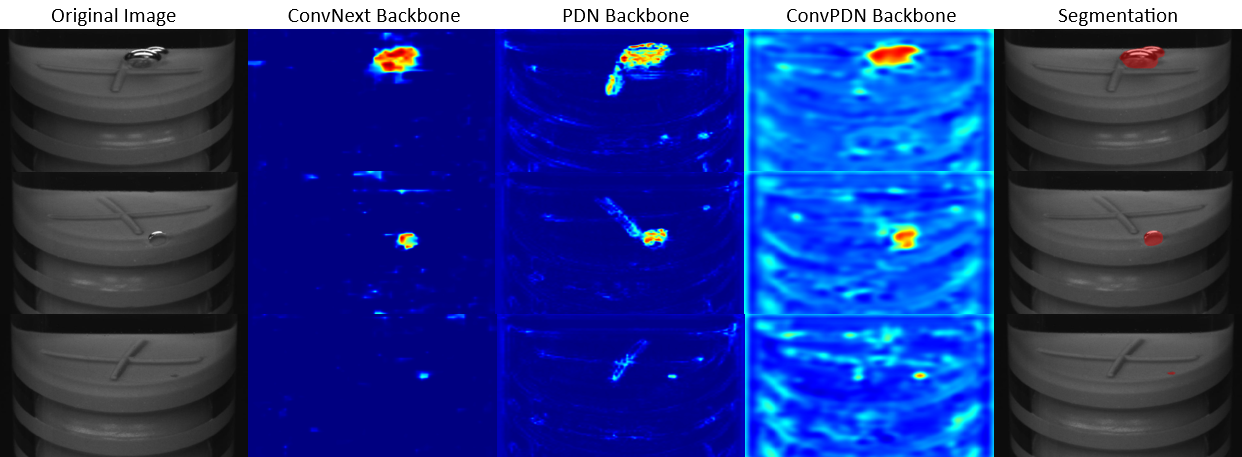

- Deep learning pipeline for ampule defect detection.

- Combined detection and segmentation for comprehensive QA.

- Data augmentation for robustness under varying conditions.

- Production-validated performance metrics.

My Role

- Designed inspection pipeline for ampule defects.

- Validated model performance under production constraints.

- Improved reliability via data augmentation and tuning.

Implementation

Language: Python

Libraries:

PyTorch

OpenCV

Results Gallery

End Result

- Automated, production-ready ampule inspection pipeline.

- High reliability meeting pharmaceutical quality standards.

- Reduced manual inspection costs and improved consistency.